Torque Wrench Basics and How to Use Them

Torque wrenches provide certainty and are gentle on screws, nuts and threads on the motorcycle.

Note: The videos are in German.

- Basic knowledge and usage

- Calculation of tightening torque

- The 5 deadly sins when handling torque wrenches

- Types of torque wrenches

- Indicating torque wrench

- Triggering torque wrench

- The correct wrench size

- Practical recommendation*

- How to use

- Adjusting the torque wrench – let's get started

- 01 – Set the reference value on the torque wrench

- 02 – Tightening the screwed connection

- Further Maintenance and Care Tips

Basic knowledge and usage

Anybody interested in working on their motorcycle will inevitably come up against the topic of torque wrenches. After all, many screw connections on the machine must be tightened using a precisely defined force. Too much force could cause the screw to break off or lead to destruction of the thread. Too little force, e.g. when tightening axle nuts or brake caliper pins, could pose a significant safety risk with potentially dire consequences.

If used correctly, the torque wrench guarantees the precise tightening torque and the optimum clamping force between the screw and thread.

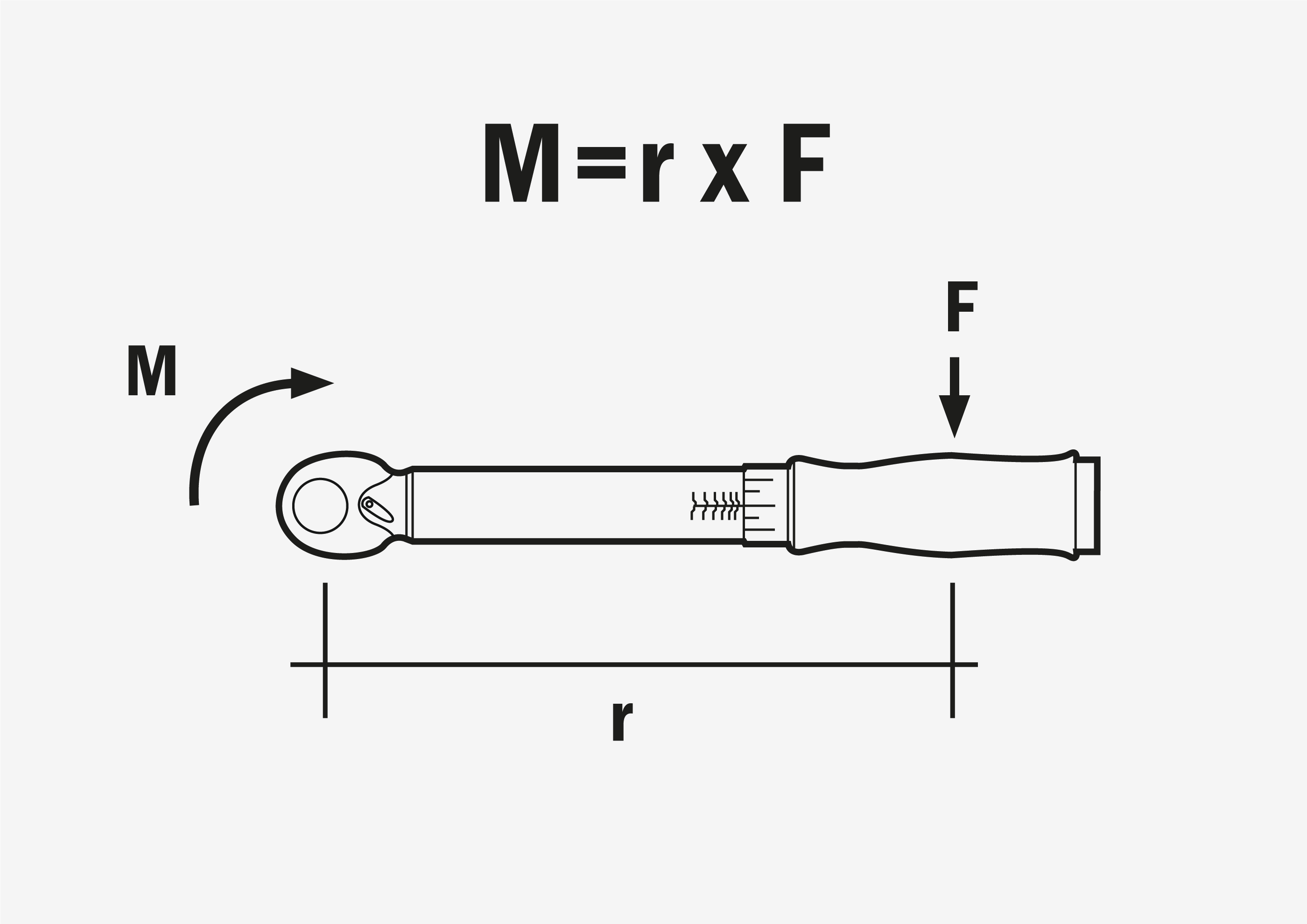

Calculation of tightening torque

Calculation of tightening torque

By the way – The tightening torque (M) is calculated from the radius of the lever distance (r) times the applied force (F).

Manufacturers provide specific tightening torques for application-related screw connections in vehicles which can be obtained by referring to the workshop manual or operating instructions for the motorcycle. Examples of these are the axle nuts, oil drain plugs, brake caliper pins, pins on the triple tree, cylinder head screws and various engine screws. If these torque specifications are exceeded, the component could deform and the resulting tension could lead to warping (e.g. of a sealing surface), a thread tearing out or could cause the pin to snap off.

Furthermore, standard tightening torques exist for standard screws, which depend on the thread diameter, thread pitch, material and quality grade. These can be used for orientation in the absence of any other specifications for a screw connection. These values can be found on the Internet, in the specialist customer- or telephone directory for metal or motor vehicle technology and excerpts of this information are also provided in Screws Basic Info in our DIY tips.

The 5 deadly sins when handling torque wrenches

- DO NOT: Leave the torque wrench at the setting used once you have finished work as this will wear out the spring.

- DO NOT: Turn the torque wrench to beyond the scale values as this will wear out the spring.

- DO NOT: Use universal joints or extension bars as this will lead to inaccuracies in the triggering torque.

- DO NOT: Take the torque wrench apart as this will lead to inaccuracies in the calibration values.

- DO NOT: Use the torque wrench to loosen stubborn screws, as this will result in damage. The calibrated values could change.

Types of torque wrenches

Torque wrenches operate according to various functional principles. A distinction is made especially between "indicating" and "triggering" torque wrenches.

Indicating torque wrench

Indicating torque wrench

The simplest and normally the most favourable form is essentially a torsion bar, whose rotation in relation to a fixed bar is represented by a value on a scale or dial gauge. When turning the wrench, the pointer must be carefully observed and the turning motion stopped immediately once the reference value has been reached.

Triggering torque wrench

Triggering torque wrench

With these torque wrenches, the reference value must be set before the application starts. A signal indicates when the reference value is reached. The signals can be heard or felt (click wrenches). However, the signal can also be a slipping (slipper wrench) or folding motion (breaking wrench) or can be shown on a display.

The most commonly used torque wrench is a click wrench and this is therefore described below together with its use.

The correct wrench size

Torque wrenches are available in different sizes for different torque ranges. Most tightening torques used on motorcycles lie between 3 Nm and 200 Nm. However, this large range cannot be covered by one torque wrench. Different wrench sizes are therefore required, depending on the area of application. The operating instructions for the motorcycle may be helpful when selecting suitable wrenches. This information is normally provided in the form of tables containing the prescribed tightening torques.

Practical recommendation*

When a large wrench, e.g. 20–110 Nm, is triggered in the lower range of the scale, i.e. 20–30 Nm, this is only slightly noticeable and certain amount of concentration is therefore required. To rule out the possibility of making mistakes, the next smaller wrench (e.g. 6–30 Nm) should be used, as the triggering signal is much more noticeable.

How to use

Working with the torque wrench requires care and practise and takes a bit of getting used to. To be on the safe side, stick to the following tips. These instructions are for click wrenches.

*By the way – The Louis range of torque wrenches spans a range of exactly 3–210 Nm.

Adjusting the torque wrench – let's get started

Step 1, Fig. 1: 40 Nm is set as shown above

01 – Set the reference value on the torque wrench

First, look up the tightening torque for the screw in the workshop manual or operating instructions. Then fasten the lock at the end of the handle. The value can be set as follows by turning the handle.

Example 1: A screw is to be tightened to 40 Nm. To do this, turn the turning handle until the reference edge, when turned to the zero position, is exactly aligned with the mark for 40 on the scale.

Step 1, Fig. 2: 44 Nm is now set

Example 2: A screw is to be tightened to 44 Nm. To do this, turn the turning handle until the reference edge is in the zero position and lines up exactly with the 40 mark on the scale. Now keep turning the turning handle until position 4 on the turning handle lines up with the vertical line of the scale.

Finally, slide the lock at the end of the handle back into the locking position. The torque wrench is now ready to use.

Step 2: Pull slowly and steadily until you hear the trigger signal

02 – Tightening the screwed connection

The screwed connection, previously tightened by hand, can now be tightened with the torque wrench. To do this, fit the torque wrench with suitable attachment (socket wrench nut or bit attachment) onto the bolt and operate the handle of the lever arm, applying a continuous gentle force.

The set tightening torque being reached is indicated by a noticeable small jerk accompanied by a click noise. Pay attention to the triggering of the wrench! On no account whatsoever should you continue tightening as otherwise you will exceed the set tightening torque.

Please note: You must therefore stop applying force after the signal, as the wrench will not do so itself!

If you get the impression during the tightening process that a bolt is unable to withstand the tightening torque or feels "soft" or similar, stop tightening it immediately. The thread is probably defective or the bolt material too soft. Check the components before the thread breaks off and the bolt potentially becomes difficult to remove.

If the component has several parallel screw connections, e.g. cylinder head, tighten the screws in stages: initially with a low torque, then a medium torque and the final torque should be applied in the third step. This allows the workpiece being tightened to settle evenly which prevents it from warping or breaking.

Also bear in mind that some components have several screw connections that must be tightened in a certain sequence, e.g. crosswise or starting from the inside and working towards the outside. In these cases always follow the manufacturer's specifications.

Once you have finished using the torque wrench, it must be unlocked and the adjustment turning handle turned back until the edge lines up with the lowest value on the scale, but not any further. The spring inside the torque wrench is only relaxed in this position. Every continuous load, whether tensile or compressive, would wear out the spring and the accuracy of the display would gradually deteriorate.

Further Maintenance and Care Tips

- Before using the wrench on a vehicle for the first time, try it out on an object which is not prone to damage in order to familiarise yourself with the mechanism. Familiarise yourself with the trigger signal with different tightening torques and make sure the tool is working correctly.

- Do not use extension bars with universal joints when working with the torque wrench, as these could lead to inaccuracies in the tightening torque.

- Do not use the torque wrench as a lever to loosen stubborn screw connections. It is not a release tool! It might cause the calibration values of the torque wrench to change.

- Many torque wrenches are not suitable for tightening screws with left-hand thread. Please check this in the instructions for use, if necessary.

- Please handle the torque wrench carefully, do not drop it or store it in a damp environment.

- Clean the torque wrench with a cloth and, if necessary, some fine oil for the metal parts. External metal parts can also be protected against corrosion with corrosion protection spray. Under no circumstances whatsoever should you take the torque wrench apart to clean it or immerse it in a cleaning solution.

- The manufacturer has adequately greased the mechanics of the torque wrench. If the torque wrench has not been used for an extended period of time, operate the turning handle repeatedly. The lubricant is then redistributed in the mechanics.

The Louis Technical Centre

If you have a technical question about your motorbike, please contact our Technical Centre, where they have endless experience, reference books and contacts.

Please note!

These tips for DIY mechanics contain general recommendations that may not apply to all vehicles or all individual components. As local conditions may vary considerably, we are unable to guarantee the correctness of information in these tips for DIY mechanics.

Thank you for your understanding.